What is UVgel Printing and Its Benefits?

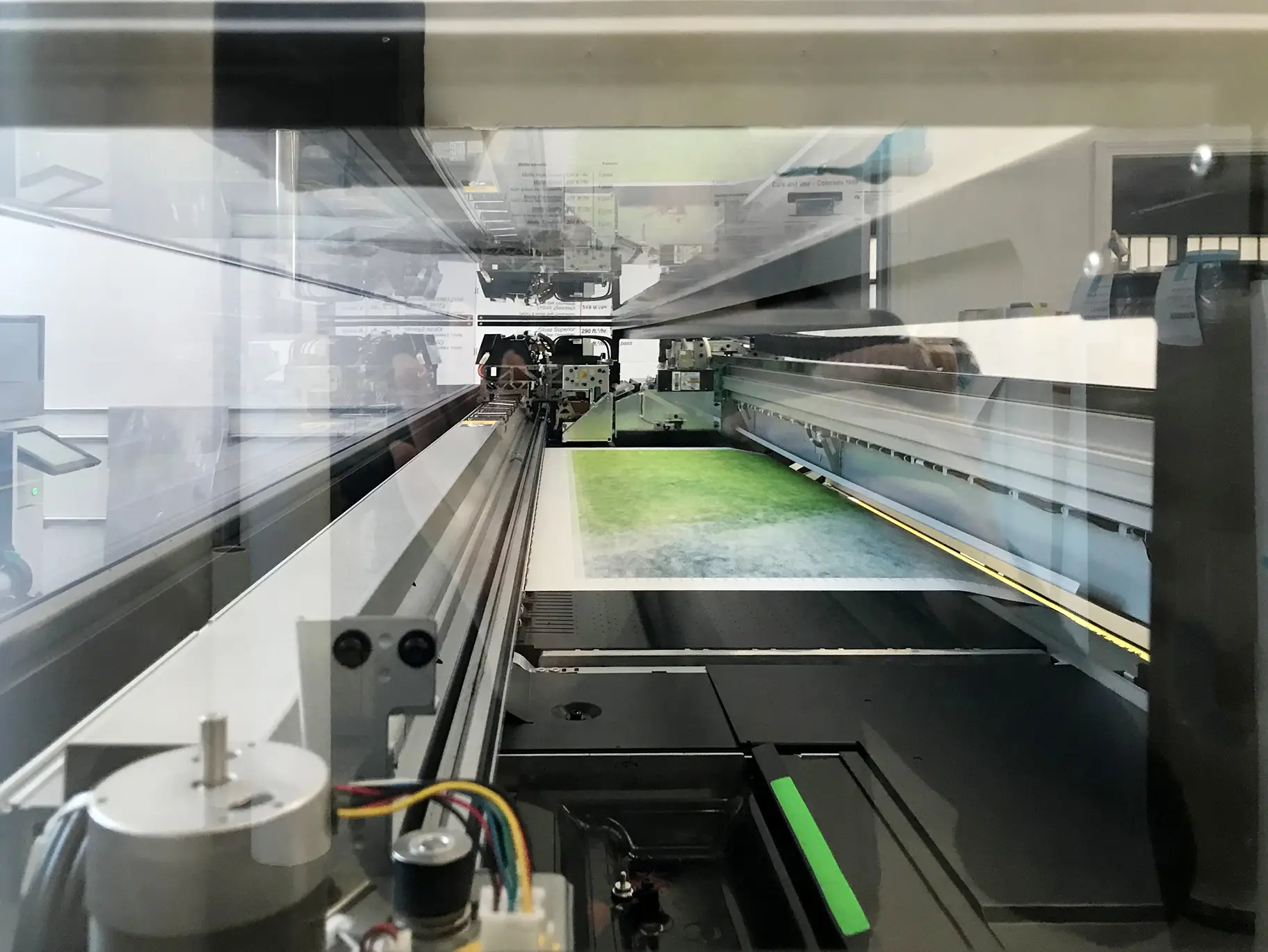

In MetWest’s unending pursuit of excellence in serving our clients, we are excited to share a transformative development in our production facility: We have shifted to UVgel printing technology for our glass film and wall covering products! This cutting-edge, award-winning innovation is set to revolutionize the way we serve our valued customers, and we are so excited to share its many benefits with our clients.

So, what exactly is UVgel, and how does it work its magic? What sets it apart from traditional printing methods, and why should you be excited about this shift? We’ll answer these questions and more in this blog.

What is UVgel Printing?

UVgel ink is a distinct type of ink recently developed for the printing industry. What makes it noteworthy is UVgel’s unique composition and curing process. In most inks, you have a base and a coloring agent. For example, aqueous inks use a water base with dye, while solvent inks have an oil base with pigment.

UVgel ink is formulated with a gel base containing pigment. After applying UVgel ink to the substrate, it’s solidified and set in place using energy-efficient LED UV lights. This results in quick and precise drying, making UVgel ink a preferred choice for producing vibrant, durable, and high-quality prints.

What are the Benefits of UVgel Printing?

UVgel Results in Extremely high image quality

UVgel printing stands out for its remarkable ability to deliver exceptional image quality. This is made possible by the ink’s unique properties. Other traditional inks always have a slight ink bleed upon contact with the substrate, each ink droplet merging slightly with the surrounding droplets. UVgel ink’s gel-based composition on the other hand ensures that each ink droplet remains precisely where it’s deposited. This precision in ink deposition results in razor-sharp prints with a remarkable resolution of up to 1800 dots per inch (dpi).

Furthermore, the ink quality results in vibrant and rich colors every time. The overall result is visually stunning, making UVgel a standout choice for all applications.

As another impressive bonus, UVgel prints maintain their high image quality, even when subjected to the stresses of folding or bending. Thanks to their enhanced stretchable properties, these prints retain their integrity and sharpness, offering a level of durability that ensures your message and graphics remain top-notch regardless of the conditions. UVgel technology’s combination of precision and durability makes it a reliable choice for those who prioritize image quality in their printing projects.

The Durability of UVGel is Unbeatable

The durability of UVgel technology is a quality that truly sets it apart from other printing methods. With its unique “print-then-cure” process, UVgel prints exhibit exceptional resilience in the face of a wide variety of stresses and damaging agents. These prints have been extensively tested and proven to withstand a wide selection of chemicals, making them a reliable choice for applications in environments where industrial-strength cleaning agents are commonly used.

One remarkable testament to UVgel’s durability is its ability to endure hours of exposure to bleach without any harm to the print. In fact, we at MetWest have personally left material samples to soak in bleach for up to 12 hours, and the prints remained unaffected. This remarkable resistance to chemicals is complemented by outstanding scratch resistance, making UVgel prints not only long-lasting but also ideal for projects where the utmost durability is required. Whether it’s in high-traffic areas or industrial settings, UVgel technology ensures that your prints maintain their quality and appearance even under challenging conditions.

With UVgel, Combine matte and gloss finishes

One of the notable advantages of UVgel technology is its versatility in delivering both matte and gloss finishes without the need for complex media or ink changes. This capability allows for the production of prints with varying surface textures and appearances in a single pass, speeding up production significantly.

Whether you need a sleek and reflective gloss finish or a sophisticated matte surface, UVgel technology allows for customization to meet your specific preferences. Furthermore, the ability to combine both matte and gloss finishes in a single print opens the door to ambitiously creative designs. The versatility of UVgel printing provides a cost-effective and time-efficient solution for achieving various surface textures and appearances, giving clients the freedom to bring their unique visions to life.

Award winning tech you can trust

You don’t need to just take our word for it. The UVgel technology isn’t just making waves in the world of printing; it has garnered recognition and trust from prestigious organizations on an international scale. The outstanding quality of print and innovative features of UVgel printers have earned them accolades such as the Red Dot Award, iF Award, and EDP Award, among many others.

Being recognized by these renowned organizations is a clear testament to the reliability and trustworthiness of UVgel technology. Whether you’re a print professional or a client seeking top-tier printing results, these awards serve as a solid endorsement that you can trust UVgel technology to deliver exceptional print quality and innovative features that stand out on the global stage.

WE hope now you’re excited too!

In conclusion, UVgel printing technology presents a host of practical advantages that can significantly enhance the printing process and, in turn, the final product. We at MetWest are excited to introduce our new UVgel printers, as they offer a wealth of possibilities for our valued clients. We look forward to providing our clients with these advanced solutions that deliver on both quality and versatility, setting the stage for countless successful and visually compelling projects.

Recent Posts

Tags

Have Questions?

Aenean imperdiet. Etiam ultricies nisi vel augue. Curabitur ullamcorper ultricies nisi. Nam eget dui. Etiam rhoncus.